It was only a year earlier that powersport industry-leader Truckboss introduced its first Flexxloader design to the personal watercraft market. Employing the same level of the ingenuity and commitment to quality that Truckboss has built a reputation upon, the first Flexxloader was a deck system that winched a cradle-mounted PWC (be it a lightweight standup or a full-sized, fully-loaded runabout) up a ramp onto an aluminum platform secured to the truck deck. Unloading the ski would go exactly in reverse, with the ski’s cradle accepting large tires to become a beach cart. And in its first year, the Flexxloader was a hit, surpassing even Truckboss’ own estimations.

As more and more units were sold, the engineers and fabricators at Truckboss began looking closer at their design to see how things might be improved for future generations. The Watercraft Journal spoke with Kent Natrass of Truckboss who explained, “The [first] Flexxloader was a real success for us. The watercraft community really accepted what we were doing and gave a lot of suggestions as to how we could make improvements. So we decided to listen and keep the most popular aspects of our initial design and incorporate the majority of ideas for improvement that kept coming up. At the end of the day we made four main improvements to the system.”

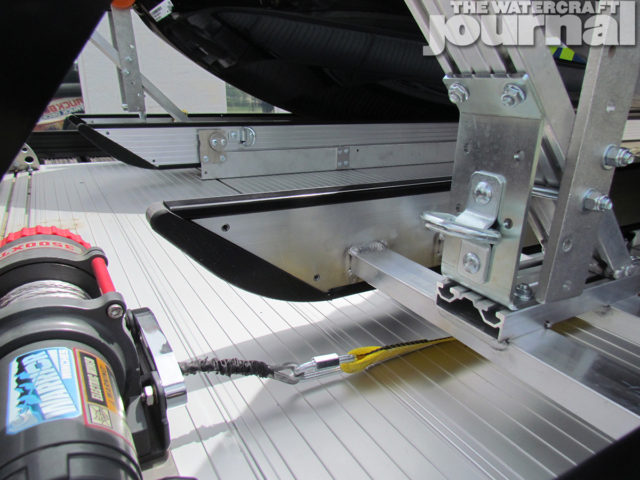

“We removed the wheels from the cradle and went to a skid system with two wheels at the back,” Natrass explained. “The skid system was trialed with our Snow Bike version of the Flexxloader and it proved to be much better at moving up and down the ramp and along our deck surface. With the new version of the Flexxloader the skid system has already proven to be to cornerstone to making loading and unloading much easier.” Using an electric winch, the cradle is easily and safely hoisted and lowered from the deck, allowing you to unload almost anywhere; boat Launches, beaches, parking lots, etc.

Natrass continued, “We introduced a guide system that attaches to the Truckboss deck. The guide system ensures that the Flexxloader loads on to the deck in the same place and the same way each time. It also incorporates a low resistant surface for the cradle skid system to move along once it is on the deck. Finally, it provides the hold down hardware for the cradle.” The new and improved guide and slide system radically improves upon the outgoing design with each cradle featuring multiple tie down points and a winch, ensuring that even full-sized runabouts will remain safely secured even while traversing rocky, unpaved terrain.

A new addition to the Flexxloader is Truckboss’ new “push back system” that makes unloading significantly easier. Natrass stated, “We designed a easy to use push back and lock down system for the Flexxloader. We recognized that some of the watercraft on our deck were around 900 pounds and that getting them moving in either direction was a real chore. So we rolled up our sleeves and came up with a system that would push the Flexxloader back off the deck when unloading and would lock it into place when loading, all with a 18V cordless drill and minimal physical effort.” Helping cut the strain of the system even further, the new Flexxloader’s ramps are now lighter and easier to engage.

Lastly, Truckboss made huge improvements to its buggy system. “The new buggy system uses better wheels for almost all conditions and is far easier to engage and disengage from the Flexxloader cradle,” Natrass explained. “Now we feel that our customers get far more than a road transportation system, they also get a tool to help them at the water, and when they get back home for storage.” Available as an option, the new Flexxloader buggy system lets the new ski cradle become a beach tote (and portable beach dock) in less than a minute. It’s also designed to act as a storage tote when your skis are put away for the winter.

What Natrass called “the Truckboss way,” all products are made in the US and Canada from the highest quality materials. “[It is] quite simply…the cornerstone of our business,” he states. “The patented Truckboss system is made almost exclusively from extruded aluminum. All of our extrusions and major components are made in the USA. This gives the system increased strength and durability that is unmatched in the market. We have some commercial customers that are moving a single deck on to its fourth truck. At Truckboss we will not compromise on quality.” And for good reason. Truckboss is a major sponsor for a variety of off-road and powersports athletes, who push their products to the very limit of their designs.

Made to hold all brands, makes and models of PWC (with a maximum load capacity of 2,000-pounds), the modular design also allows the Flexxloader to be used on all full-sized, non-commercial pick-up trucks. Equally, its exclusive No-Maintenance anodized finish will keep it corrosion-free, even in the harshest (read: saltiest) of environments like the Blowsion Surf Slam, and the secure and weatherproof storage under the deck will keep items dry and locked.

Obviously, owning a Flexxloader can effectively eliminate the use for a trailer, especially if storage space is an issue, if you’re venturing to locations that can be only accessed by four-wheel-drive, or if you simply hate trying to back your trailer down the launch ramp. But many are finding Flexxloaders as being useful in conjunction with their trailers, allowing them to haul more PWC to the shore, or towing a UTE, quad or Side-by-Side on a small trailer with their skis on the truck deck. Natrass commented, “Owing a Truckboss deck equipped with a Flexxloader changes not only the loading and unloading experience for PWC owners but the transportation experience.

“We called it ‘Flexxloader’ because of the flexibility it offers. By ditching the traditional PWC trailer, users can avoid highway speed limit restrictions and get to the fun a little faster. Once there they have the option to unload at a boat launch, if the launch is backed up, the Flexxloader can be unloaded almost anywhere, coupled with the buggy system, and rolled right to the water,” Natrass continued. “Again, we want our customers to get to the fun a little faster. Once in the water the Flexxloader can serve as a dock during the day and even overnight. When it is time to load, the busy and often frustrating boat launch can be avoided and our customers can get on the road a little quicker. And once home, the Flexxloader and buggy system are perfect for rolling around the watercraft for storage.”

In all, the Flexxloader effectively turns your truck into its own trailer, while greatly enhancing the benefits already imbued in your existing truck. Moreover, these benefits can now be truly realized with the improvements that Truckboss has made to the Flexxloader for 2016, making loading and unloading now significantly safer – and quicker – than ever.