We at The Watercraft Journal have a bit of a love/hate affair going on with Belassi. It’s not that we’re angry or vengeful against the manufacturer of one of the most powerful personal watercraft ever made, it’s just that we’re on the other side of the damned planet and haven’t been given the chance to ride one yet. So, until we can get our hands on their new 333-horsepower, turbocharged Burrasca runabout, we’re left gleaming all of the information we can from press releases and third-party info.

Earlier this month, the Austrian company threw open its doors and arranged for a photoshoot of its Linz, Austria headquarters to shine some light on the process that lead to the creation of their self-described “ground-breaking” runabout. Belassi was kind enough to send us their recap of the tour; and while we often (more like never) cut-and-paste press releases and call them “original content” we did think it worth letting Belassi explain their facility in their own words. So, with no further ado, here’s what they had to say about themselves:

“In July, after taking part in different competitions, the Belassi team stated that they were satisfied with the results their personal watercraft had earned, which made them realize the huge potential of their creation. This events gave them the idea for a new project, a new improvement for their Burrasca; they decided to equip it with a racing setup, so that every customer would live ‘the full Belassi Experience’.

“Quite a few images showing the process of building a Burrasca and Belassi technicians working inside the headquarters have been released. Entirely made in the Belassi factory, it takes the utmost attention and passion. Over twenty-five assembly steps cover more than two thousand parts to get the perfect mixture of the best and most innovative materials, techniques and know-how that is the final products.

Above left: The interior of the Belassi offices. Above right: Research and development department.

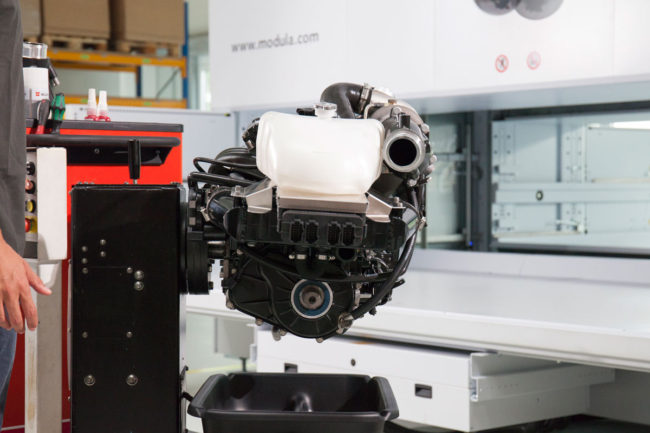

“The first assembly phase is the installation of the front plate, steering cable, bracket and the high-tech aluminium adjustable sponsons. The water outlets, hoses, top deck and double-chromed cover for the water-cooled exhaust system are mounted next; followed by the sealants, the engine Silent Block and EPP. Then come the adjustable rear flaps, the electric parts and other. The I3C16 engine — Marine 3 cylinders, 4 stroke — is preassembled and installed, as are the trim, reverse pipes, 3K carbon muffler and bilge systems. The battery, the charge air system and the innovative x-frame, made of light 3K carbon, get placed inside the Burrasca, adding an internal support for the durability and safety of the runabout.

“The drive shaft, the reverse flap and the engine hood, with its innovative and unique opening system are put in place, allowing for a comfortable inspection of the engine compartment.

Above left: Set up of engine I3C16. Above right: The ergonomic sport seat.

Above: The packaging is specifically designed for Burrasca.

“The finishing touches are the covers — steering, side and pads — and finally, the ergonomic sport seat with its carbon fiber base. This seat, made in Italy, is durable, resistant and certified, and features the company’s trident-like logo. To top it all off, the packaging is specifically designed for Burrasca, to protect the precious Austrian personal watercraft from scratches and from the risk of ruining its red glossy finish.

“This means the production is going strong and that Belassi is steadfast in his visionary project of delivering a unique runabout, with a racing-like feel yet designed to be both elegant and sophisticated. It’s a finished product that meets the company’s high standard ideals.”

https://www.youtube.com/watch?v=o8oo6s-a0ys