At first blush, it’s pretty natural to want to size up Sea-Doo’s 325-horsepower ACE engine alongside Belassi’s 400-horsepower 1.6L 3-cylinder. Heck, even we at The Watercraft Journal originally went that route when outlining this very story, and rightly so: Sea-Doo’s latest centrifugally-supercharged 3-cylinder has been the darling of racers, tuners and performance enthusiasts since it’s reveal in late 2023.

Yet, what many are discovering is that the 325 ACE is operating close to the engine’s peak output, and that fact alone, is not by accident; Belassi’s Sergiy Borakovskyy explained to WCJ, “Rotax and Yamaha engineers have achieved remarkable engineering feats, delivering exceptional products that balance cost and power within stringent design guidelines.”

Constrained by so many factors, manufacturers like BRP are forced to develop new products within tight legal and financial confines. “In contrast,” Borakovskyy continued, “our lower production volumes afford us greater flexibility in engine design, allowing us to create high-performance designs with minimal cost differences compared to high-production optimized designs.”

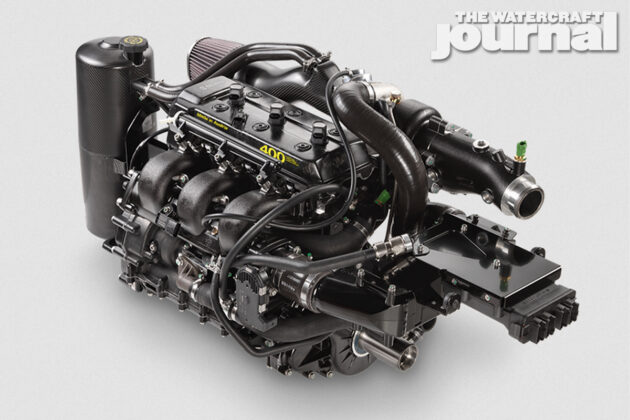

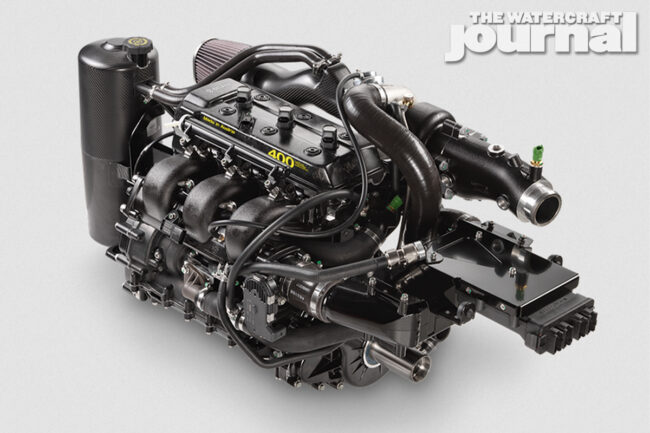

This flexibility permitted Belassi to develop a turbocharged 4-stroke that produces considerably more power while working far less than the current 325 ACE. The Belassi 400 Turbo powerplant produces its peak output of 400-horsepower @ 8,200rpm – some 75 ponies more than Sea-Doo and at 50-less rpm. But as we continue, you’ll discover this to be anything but an apples-to-apples comparison.

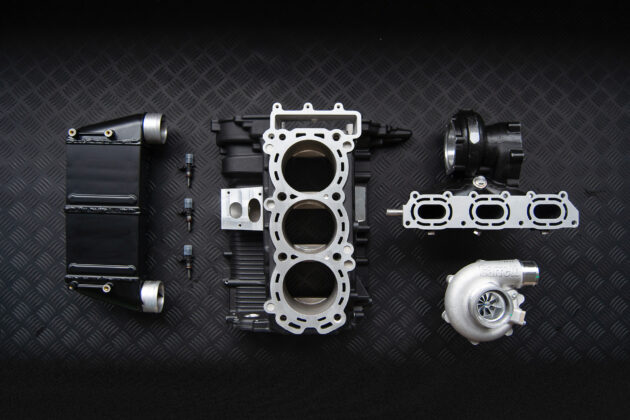

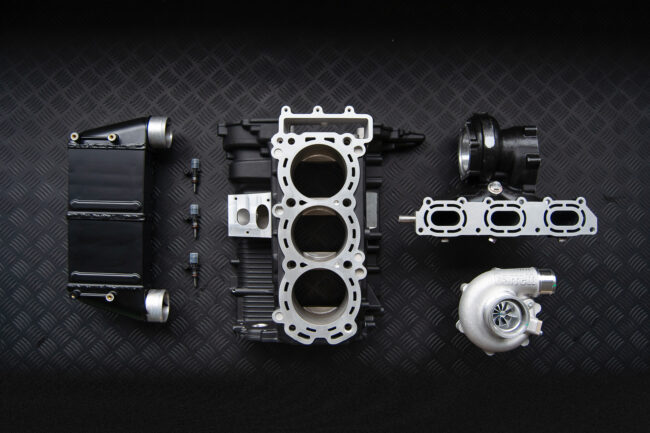

The Belassi’s open-loop, water-cooled 1,602cc triple cylinder comes in with 28cc’s beneath the Sea-Doo, achieved by operating with an identical bore size (100mm) but slightly less stroke (68mm vs. 69.2mm). The loss in total stroke length is made up in piston dome height and chamber quench, upping the Belassi’s cylinder compression to 9.1:1, significantly higher than the ACE’s 8.45:1.

And don’t worry, the increased compression is no issue for Belassi’s closed-deck engine block design. More rigid and offering greater cylinder support, the aluminum block experiences negligible shift during casting and less detrimental harmonics at high rpm. Forgoing a ductile sleeve, each cylinder is coated in Nickel Silicon Carbide (NSC). Unlike popular coatings like Nikasil, NSC shows no visible cross-hatching after being honed.

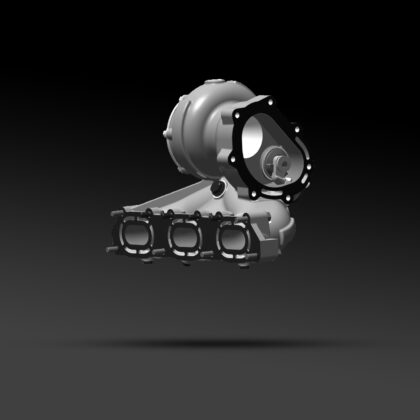

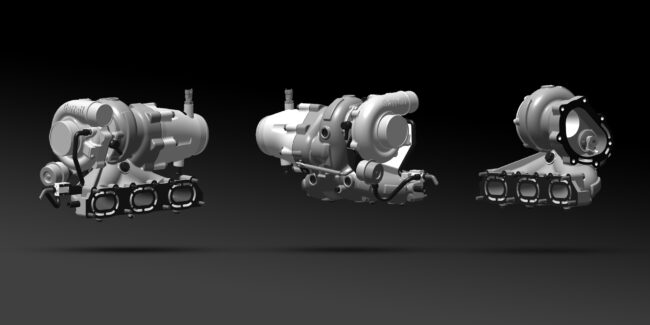

Of course, more compression is only a part of Belassi’s secret to producing more power at lower rpm with less displacement. The big secret is efficiency. Unlike superchargers that are spun from the engine’s drive, Belassi’s 400 Turbo requires zero parasitic draw to spool up the turbo. Rather, a uniquely cast, compact exhaust manifold is not only water-injected but a “natural water lock” for optimum temperature regulation.

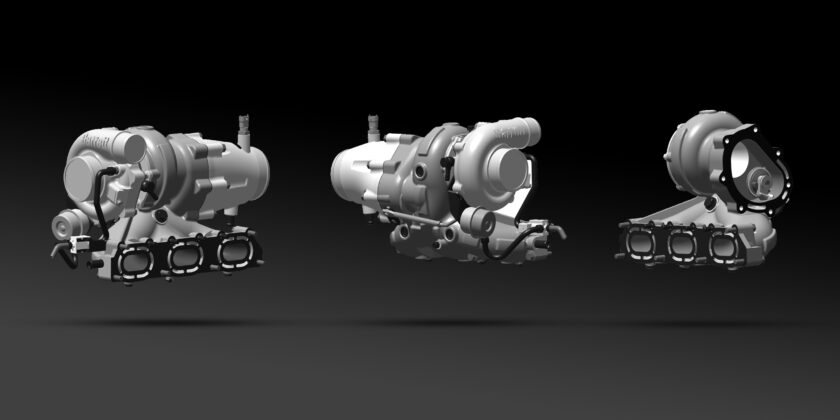

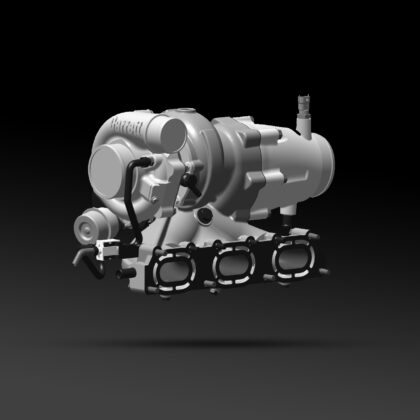

See, keeping turbo temperatures low is a tricky job and is handled three ways: First, as the Belassi’s dry sump oiling system maintains engine oil pressure – even in high speed turns – it also forces oil through a heat sink to regulate temperatures. This same oil is pumped into the turbocharger for lubrication, keeping oil temps consistent ensures the Garrett turbo’s efficacy at generating boost.

Secondly, the exhaust spooling the turbo’s positive side is rapidly-cooled before reaching the end of the manifold. Integrated into the manifold is an electromagnetic wastegate, regulating boost pressures at all times with a single Lambda port. Lastly, a custom two-stage intercooler features dual cores and shorter charge tubes, bringing down intake temps resulting in a denser, more powerful intake charge at the throttle body.

Per Belassi, “All [of these] components are working as one in a compact design that allows a better turbo response with minimal turbo lag and a great balanced exhaust pulse.” The final result, as we’ve detailed here, is a consistent and proven 400-horsepower; but that’s not where this story ends:

Belassi needed the 400 Turbo to not just perform but to last. “Our primary goal is to provide a solid foundation for new and innovative marine products, regardless of their design,” Borakovskyy added. This meant the engineers were told to push the Turbo 400 further, stating, “We confirm that the fuel system is capable of matching the Garrett charger, which, on paper, can deliver the airflow required for 550 horsepower.”

And no, this result did not come from exotic parts upgrades or pumping in high octane race fuel. This was simply by unrestricting the Belassi’s intelligent engine control system that otherwise, safeguard the engine from “less experienced” riders. This same software increases boost at low engine rpm for superior acceleration either from a halt or pulling through the apex of a turn.

Ultimately, Belassi would prefer that its flagship powerplant – the Turbo 400 – remains to be seen as its own creature. Certainly, similarities between it at the 325 ACE can be drawn between the two, but even Belassi’s own CEO Christopher Wilkinson cautioned against making such comparisons:

“We understand that direct comparisons to the 325 are inevitable. However, [a] more relevant comparison would be the investment required to upgrade a Sea-Doo or Yamaha with a turbo system, including all necessary fuel and control system upgrades to meet OEM specifications and sustain 400 horsepower.”

While the Turbo 400 is anything but simple the formula isn’t over-complicated. Groundbreaking innovations abound in this engine just as much as plain old experience; and that combination makes for a sturdy foundation for a world class performance marine engine that doesn’t need to reinvent the wheel, just brilliantly improve upon how well it works.