For most personal watercraft owners, the experience begins at the dealership or boat ramp. What remains unseen is the complex manufacturing process required to transform raw composite structures and mechanical components into a finished Sea-Doo watercraft. Recently, The Watercraft Journal was invited to tour BRP’s Sea-Doo assembly plant in Querétaro, Mexico—a facility responsible for producing the majority of Sea-Doo personal watercraft sold worldwide.

The visit offered rare access to the full assembly process, providing insight into modern personal watercraft manufacturing, quality control procedures, and the scale required to support global demand for Sea-Doo models ranging from entry-level recreational units to high-performance and touring platforms.

The Querétaro Facility: Sea-Doo’s Global Production Hub

Located approximately three hours northwest of Mexico City, the Querétaro plant serves as the central assembly location for Sea-Doo watercraft. The facility employs thousands of workers across multiple shifts and operates nearly continuously during peak production periods. From this single location, completed watercraft are shipped to more than 130 countries worldwide.

The plant itself is expansive, with multiple assembly lines operating simultaneously. Each line is organized around specific product families, allowing Sea-Doo to produce both its smaller, lightweight Spark models and its larger GTX, RXT, and Wake series watercraft within the same complex.

Engines, electrical systems, jet pumps, and molded hull components arrive in carefully organized staging areas before entering the assembly line, where they are integrated into complete watercraft.

Hull Preparation: Where Each Watercraft Begins

The assembly process begins with composite hull staging. These unfinished hulls form the structural backbone of each watercraft and are molded from composite materials engineered to balance strength, weight, and durability.

At this stage, the hulls appear as bare shells, lacking the recognizable features of a finished personal watercraft. Each unit is tagged and digitally tracked throughout the assembly process, allowing technicians to monitor installation progress and maintain detailed production records tied to each individual watercraft.

From staging, hulls move onto the primary assembly line where internal components begin to take shape.

Installing Engines, Fuel Systems, and Internal Components

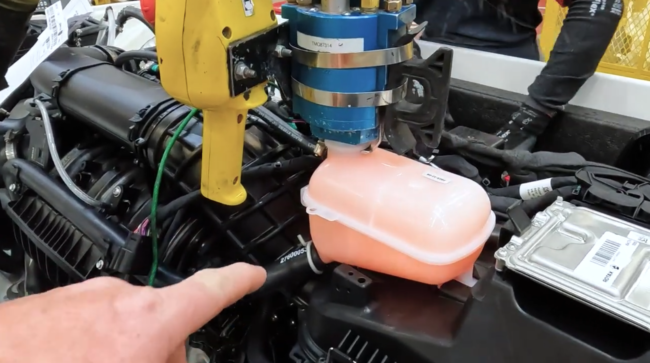

As hulls advance along the assembly line, Rotax engines are carefully lowered into place using overhead lifting systems designed to ensure precise alignment. Fuel tanks are installed and pressure tested prior to final integration to verify system integrity.

Electrical wiring harnesses are routed through the hull, connecting ignition systems, sensors, and digital instrumentation. Each installation step follows a carefully controlled sequence designed to ensure proper fitment and system functionality.

Digital torque tools are used to tighten fasteners to exact specifications. These tools record torque values electronically, allowing assembly data to be logged and referenced if necessary.

Separate Assembly Lines for Spark and Full-Size Models

Sea-Doo Spark models follow a slightly different assembly path compared to full-size fiberglass-based watercraft. Their lightweight Polytec construction and simplified architecture allow for efficient assembly while still incorporating the same quality control principles.

Larger models—including the GTX Limited, RXT-X, and Wake Pro—require additional assembly stages due to more complex systems, larger engines, and additional electronic features.

Despite these differences, both assembly lines operate under similar procedures and oversight.

The Hull and Deck “Marriage” Process

One of the most visually distinct stages of assembly is the joining of the upper deck to the hull. Prior to joining, technicians apply industrial adhesive along the bonding surfaces to ensure a secure structural connection.

Robotic systems assist in applying adhesive evenly, after which the upper deck is carefully lowered onto the hull and secured.

This step transforms the watercraft from an open assembly platform into a fully enclosed machine.

Testing and Functional Verification

Testing procedures are conducted throughout the assembly process. Engines are started and operated briefly under controlled conditions while connected to water circulation systems that simulate cooling during normal operation.

Electronic systems, instrument displays, and sensors are verified to ensure proper operation. These tests help confirm functionality before the watercraft proceeds to final inspection.

Final assembly steps include installation of seating, trim components, and model-specific graphics.

Final Inspection and Global Distribution

Once assembly and testing are complete, each watercraft undergoes final inspection. Technicians visually verify component installation, system completeness, and overall fit and finish.

Finished units are then wrapped, secured in shipping frames, and staged for transport. Trucks depart regularly from the facility carrying completed Sea-Doo watercraft to distribution centers and dealerships around the world.

A Rare Look Inside Modern Personal Watercraft Manufacturing

Touring Sea-Doo’s Querétaro assembly plant provided valuable insight into the processes involved in building modern personal watercraft. From composite hull staging and engine installation to electronic integration and final testing, each stage reflects the coordination required to support global production.

For enthusiasts, seeing how Sea-Doo watercraft are assembled offers a deeper understanding of the engineering and manufacturing behind the machines riders use every day.

The assembly process itself remains largely unseen by the public, making opportunities like this tour a rare glimpse into the manufacturing side of the personal watercraft industry.