“Cellulose Nanofibres” sure doesn’t sound like a topic that belongs on the pages of The Watercraft Journal. After all, it’s not a redesigned cylinder block, it doesn’t go 142 mph, it doesn’t do backflips and it doesn’t take home trophies, right?

According to Yamaha, cellulose nanofiber actually does win races, help break speed records, and plays a vital role in advancing the personal watercraft industry on both the pleasure and competitive sides, and is a step in reducing the jet ski industry’s carbon footprint.

According to NBIC +, a leading nanotechnology website, Yamaha is perhaps leading the emergence of powersport use of cellulose fibers.

According to an October 28 NBIC+ article, the 2024 models of Yamaha WaveRunner personal watercrafts and sports boats use “the first mass produced composite parts based on plant-derived cellulose nanofibre (CNF) reinforced resins.”

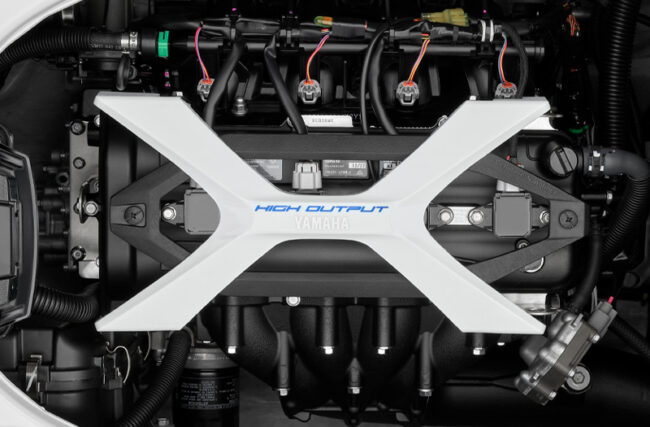

Specifically used in the power unit engine covers, these parts were developed in a partnership with Nippon Paper Industries specifically to handle the effects of seawater and high heat.

The article states that these resins, reinforced with the cellulose nanofibres, “achieve strength and other material properties equal to or greater than existing materials and in addition to being over 25% lighter than existing resin materials, it also has excellent material recyclability properties and can be used repeatedly.”

According to Yamaha technical sheets, CNF reinforced resin is a new high-strength material manufactured by kneading and dispersing CNF, a biomass material made from wood resources, into resins such as polypropylene.

The incorporation of products such as the plant-based cellulose nanofibres is part of Yamaha’s published sustainability initiatives, working on the top-level goal of reducing the risk of marine ecosystem destruction and fishery resource depletion by increasing the recyclability of marine products.

An August 25 press release stated, “Yamaha Motor Co., Ltd. announced today that it will adopt plant-derived cellulose nanofiber (CNF) reinforced resin for marine products as an initiative toward reducing CO2 emissions and the Company’s environmental footprint. In developing the material, Yamaha Motor has reached a collaborative agreement with Nippon Paper Industries Co., Ltd. (Headquarters: Chiyoda-ku, Tokyo). This is the world’s first practical use for vehicle parts.”