Oh the pains we take to look good. Nobody likes their ski looking like it was just pulled out of the sideyard, especially when joining a group for a full day’s ride. For those of us in wetter climates, mold and mildew can grow quickly, discoloring seats, traction mats and more (if left to flourish). Dirt, pollen, and heavy caked-on waterspots are just as bad. Moreover, the damage that neglect can occur when left untreated can result in permanent wear and tear, if not wholly expensive to repair.

Our 2019 Yamaha FX HO WaveRunner came to us after a relatively short life of rather brutal living. The vehicle itself was the very same used for all of the 2019 product photography and video; the early media introduction; dealership demonstrations and much, much more. By the time we received it, signs of wear were everywhere – despite its short 20-plus-hours of operating time. Frankly, it hurt our hearts a little; like rescuing a neglected or mistreated dog from a shelter. From there it became our mission to bring back its as-new luster.

As always, we whipped out our trusty pressure washer and knocked off as much of the topical dirt, pollen and grime with our 25-degree nozzle. We also came in close to try to blast off any spots where dried-on sunscreen, grease, grim and tree sap had collected. Then we switched to a soap broadcaster nozzle and filled it with (*gasp!*) XPS Boat & PWC Wash and Wax. Not because we prefer it over any other brand, but because we have a ton of it to use. Plus, it really does do a nice job.

The first issue pertains to a couple of cosmetic decisions Yamaha designers have been hip on for some time now: white bumpers, rub rails and seats. Obviously, each of these items are made from different materials, receive damage in different ways, and require unique solutions to be cleaned. For 2019, the new FX models feature large portions of white plastic bumpers, both at the rear corners as well as at the front. The six pieces (three at each end) are made from durable plastic that also happens to be textured.

The texturing of these pieces also makes them porous, meaning that dirt, grime and other contaminants can embed themselves making most cleaners ineffective. We tried the usual suspects: vinyl cleaners, general surface cleaners and even PWC brand-specific cleaners to no avail. What we did find was that non-chlorinated brake cleaner applied to a microfiber towel works astoundingly well. Modern non-chlorinated brake cleaners from brands like CRC’s Brakleen do not leech out valuable oils from the plastic and is non-flammable as well.

For tougher stains, we wetted a Mr. Clean Magic Eraser and rubbed on the particularly nasty spot. Once satisfied, we rinsed off the bumper, and applied a suitable vinyl protectant. While our methods are somewhat unique, we also don’t want to leave those harsher chemicals on the plastics for too long. We also purposefully avoided any agents or cleaners with bleach as it could discolor the Yamaha’s traction mats or blue highlight trim parts.

The white rub rails are not nearly as porous but can be discolored nearly as easy. We found the Magic Eraser worked swimmingly here as well, as the WaveRunner had (what we believed to be) dried tree sap hardened on the front fairings, fender and railing. And like the bumpers, we watered down the rail once we were done and coated it with a vinyl protector. We’ve heard that Magic Erasers do tend to leave a visible chemical film on darker plastics, so we were mindful to only use it on white, and to wash it off once we were done.

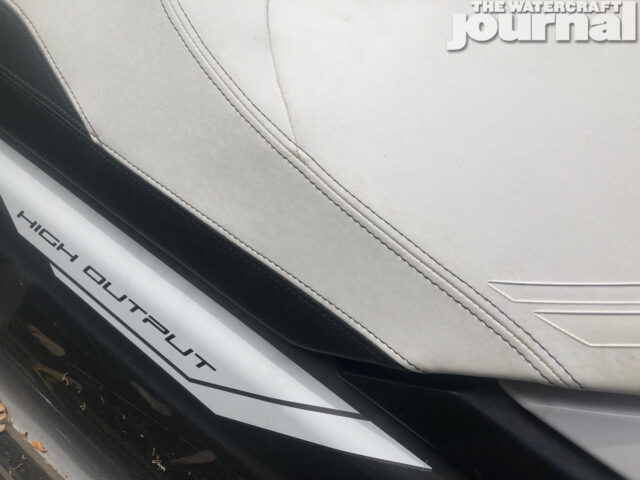

White vinyl seats are nothing new to boating and personal watercraft; yet, the materials used are. Yamaha’s newest WaveRunners employ a durable, tear-resistant canvas that isn’t slick like old vinyl seats of yesteryear. These new seats provide improved grip and traction without chaffing exposed skin and also reflect heat, so they won’t scald after sitting in the sun too long. With the new material comes new ways of treating them. Vinyl cleaners simply cannot penetrate the tightly woven fibers.

We attempted a little of our brake cleaner on a rag in a small section and weren’t happy with the results either. So we skirted off to a local boat dealer for suggestions. While we were showing discoloring from dirt and exposure to the elements, we weren’t showing signed of the dreaded “pink mold” which often appears with white seats. The dealer’s service department suggested we try Babe’s Seat Soap, a dedicated upholstery cleaner meant for larger pontoon boats and even outdoor furniture.

Not a slick coating but an actual fabric cleaner, we found that the Babe’s Seat Soap lathers quickly and penetrates into the seat material with a little scrubbing with a microfiber towel. Babe’s worked well on the white panels but struggled to really deliver the finish we wanted on the seat’s darker center section. Here, the Starbrite Ultimate Vinyl Clean stepped in. While, not as successful in cleaning the white portions, it did get the last few spots off of the black panels. So a marriage of the two is what we found to be the most successful.

Much to our chagrin, the beautiful CNC-cut Hydro-Turf traction mats are also a massive pain in the butt to get mud out of. The pressure washer couldn’t do it. None of our upholstery or vinyl cleaners could cut the mustard either. The mats feature a very fine, horizontal pattern that red Georgia mud has simply penetrated and refused to leave. So we pulled out the big guns, and put a bristle-topped can of Turtle Wax Performance Plus Power Out! Upholstery Cleaner to work.

Purchased after a very angry toddler dumped fruit-and-vegetable smoothie in the family car, the industrial-grade upholstery cleaner was our nuclear option when it came to cleaning and restoring our traction mats – and boy, did it not disappoint. Scrubbing the rich oxidizing foam into the mats was all it took. We literally wiped down the mats with a towel and BAM! they looked as good as new. It was also the most laborious part of our day, but well worth the effort.

Being left outside, the WaveRunner had collected quite a bit of debris during a very active Tennessee springtime, and needed a little bit more detailing than what we have given to previous loaner units. This meant whipping out the detailing “toothbrush” to get into the smaller cracks and crevices. One particularly problematic spot was the gap between the LCD digital touchscreen dashboard and the top of the steering cowl, where leaves and pollen had nested. That too required a bit of time, but the right tools makes for easy work.

While sitting in the seat, we figured it was the right time to install our Factory Yamaha Accessories’ RAM mount puck and cup holder. These two items didn’t come with our FX HO a little less than a month ago, but were “must have’s” on our list. We have a handheld Garmin GPS that we use regularly for navigation and data gathering, and would be lost without it. So too was the cup holder, which allows for taller water bottles and drinks to be carried at speed without fear of toppling out. (FYI, Yamaha sells and packages each of these electroplated hex-head screws separately, so pay attention to order accordingly.)

Speaking of hardware, we also noted that many folks online were painstakingly removing all of the exposed hex-headed screws and either having them replated or simply replacing them with stainless hardware. This is because the coating on the factory screws is thin, and does not guard against discoloring, scaling and rusting well at all. While nowhere near as permanent of a fix, we found simply scuffing them on a red Scotch-Brite pad to knock the loose scaling off and dusting them with a few passes of Rust-oleam semi-gloss enamel (and a pass of gloss to replicate the factory sheen) made for a good semi-solution.

The final act of the day was also our most controversial. To many, there is no greater technology than ceramic coatings. And rightfully so, as the hard-bonded material provides a near-perfect protecting layer over paint. Unfortunately, the process is exceptionally laborious, requires several hours to apply, longer to cure and if done wrong, can actually damage paint and other surfaces. Considering this, automotive and marine cleaner and detailing leader, Meguiar’s developed an advanced Hybrid Ceramic Wax.

The one-step spray was painstakingly developed to simplify the ceramic coating process; and while Meguiar’s itself admits won’t provide the same level of protection as a professionally-applied ceramic treatment, does provide UV and contaminant protection and durability far beyond that of a conventional wax that is both easy to spray on, rinse off and dry. Because our FX had never been coated with Meguiar’s Hybrid Ceramic Wax, we needed to first spray on and dry off to set an “initial application.”

The spray comes out as a thick, high viscosity spray that can go on all surfaces (including decals, plastics and even upholstery, although we avoided the traction mats and seats, as well as the touchscreen). With a microfiber towel, we wiped down and dried the ski completely – not needing the multiple passes a wax job normally requires. Then, per Meguiar’s instructions, reapplied the Ceramic Wax and brought out the hose again.

Spraying from the top down with a “strong stream,” we rinsed the Yamaha down a second time. Per Meguiar’s, “the hydropower of this rinse will spread the product, coating all the exterior with our Hybrid Ceramic protection.” After doing so, we dried the ski off again, and viola! We had a newly ceramic-coated WaveRunner. In all, the process took us about 3-and-a-half hours, but that included taking pictures and stopping to try new and creative ways to rid those pesky stains – so expect to spend half the time replicating our results.