Let’s talk about something super exciting: regulating crankcase atmosphere. To the layman, this isn’t really sexy stuff and will likely cause most of you to tune out right about…now. But for those still reading, I’m going to explain how regulating internal engine atmospheric pressures (ie. crankcase pressure) will not only ensure the longevity of your personal watercraft’s engine, but will actually help pick up some power.

An internal combustion engine, it’s most basic form, is an air pump. Air goes in, air goes out. The energy created and dispersed in this process is the byproduct we use to power modern machinery. The effectiveness of that process is predicated upon the engine’s efficiency. When an engine is properly sealed – machined tolerances, properly torqued hardware, gaskets and piston rings – it will often run optimally.

When an engine isn’t properly sealed, things go south pretty quickly. Improperly gapped rings can permit blow-by and oil contamination. Detonation can occur. Compression can be lost. Gaskets can be bubbled, burned or blown out. And of course, water can penetrate into the oil, or worse, the cylinders and hydrolock the engine.

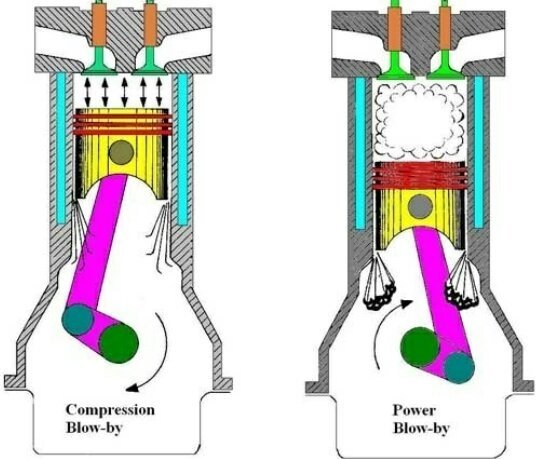

Not nearly as catastrophic but equally as terminal is excessive blow-by. Blow-by, as the name suggests, is when during the compression stroke, unspent air and fuel in the cylinder literally blows by the piston rings and enters into the crankcase. The raw fuel and carbon particulates quickly contaminate the engine oil as the compressed, heated air pressurizes the atmosphere within the crankcase itself.

Thankfully, today’s modern 4-stroke engines feature incredibly well-designed multi-valve combustion chambers with machined quench surfaces, and valve reliefs integrated into the piston crowns, which was all high-end racing technology only a few years ago. Piston ring technology has also found its way into stock equipment, with multiple precision ring grooves, compression rings, oil control rings and return drains.

Yet, even in the face of these innovations, blow-by can occur – particularly in high compression or heavily-boosted applications (turbo or supercharger). When the compression charge of ignited fuel and condensed supercharged air exceeds the efficiency of the cylinder bowl design, piston shape and rings, the excess pressure seeks out the weakest route to escape, which is often by blowing by the piston rings.

Modern engine tuners have also found that poor or inefficient ignition and timing of the return stroke and/or the exhaust cycle is also a contributor to blow by. Commonly referred to as “prolonged duration,” the cylinder pressures are not permitted to escape through the exhaust valves fast enough, and thereby, look for another way out.

Once entered into the crankcase, the atmospheric pressure begins to build. This superheats the air and oil – far faster than what the engine was designed to withhold, consequently boiling the oil into a miasma of oil mist and fuel vapor. If left untreated, unspent fuel can break down the oil’s protective attributes on sensitive bearings and rings, causing excessive heat and accelerated wear.

With the engine sealed, this pressure struggles to find release, and will eventually push oil up past the piston rings, causing the engine to start burning oil, blowing white smoke out of the exhaust. Many modern engines feature a PCV valve that plumbs the crankcase to the engine’s intake – either before the throttle body or directly into the manifold. The Positive Crankcase Valve is meant to maintain an equilibrium of healthy crankcase pressure and an internal engine temperature in a normally operating engine.

Yet, when heavily-contaminated crankcase atmosphere blends into the incoming air-and-fuel mixture in the combustion chamber, the mixture can cause pre-ignition (when super-heated fuel detonates before the timing spark) or detonation (also known as “knock”, when the mixture detonates post-ignition timing). Both are highly detrimental to the health of the engine and can quickly weaken and destroy valves and pistons.

In supercharged watercraft – particularly today’s 300-horsepower Sea-Doos – the PCV routes into the air intake prior to the throttle body. This means that the contaminated, oil-and-fuel heavy fog from the crankcase passes through the intercooler uninterrupted. This vaporized oil can coat the cooling fins and core tubes, stiffing the intercooler’s ability to cool the intake charge.

A far less catastrophic occurrence is excess windage. Windage is when too much oil clings to the throws of the crankshaft, connecting rods and piston skirts, literally weighing these reciprocating parts and throwing off their carefully balanced weights. Windage can slow down your engine’s operation and, again if left unchecked, can cause unusual wear patterns in the cylinder walls.

A far less catastrophic occurrence is excess windage. Windage is when too much oil clings to the throws of the crankshaft, connecting rods and piston skirts, literally weighing these reciprocating parts and throwing off their carefully balanced weights. Windage can slow down your engine’s operation and, again if left unchecked, can cause unusual wear patterns in the cylinder walls.

As blow-by saturates the crankcase atmosphere with super-heated oil, it chokes the air inside the crankcase, coating the crank, rods and pistons with a heavy layer of lubricant – far more than these parts need. Of course, a direct contributor to oil windage is excess/over-filled oil levels.

RIVA Racing’s own Brian Rosencrantz explained: “A common cause of poor performance is over-filled engine oil. Failure to follow the correct procedure will result in the ski being over-filled. This causes decreased engine performance due to windage losses in the engine.”

Thankfully, resolving these issues is surprisingly easy. As Rosencrantz noted, properly following the oil filling instructions outlined in the service manual of your personal watercraft will ensure that you will not over-fill your engine, even if your dipstick might say otherwise. Secondly, we found that a supplementary crankcase breather, such as RIVA’s Sea-Doo 4-TEC Catch Can/Engine Breather Kit works flawlessly.

The RIVA Catch Can works as an intermediary between the PCV valve coming from the crankcase and the feed into the intake. This added step helps separate the super-heated oil vapor and unspent fuel, permitting only positive air pressure to filter through into your intake – ensuring a healthy crankcase atmospheric pressure without contaminating the intake charge – all while improving intercooler efficiency by preventing oil contamination which lowers thermal efficiency.

The catch can literally collects the oil and fuel byproduct that can be drained occasionally via a petcock valve (you don’t want that mixture feeding back into the crankcase). The kit is incredibly easy to install, mounts to the side of the 300 ACE’s engine block, and comes with all of the necessary hardware to do it in a matter of an hour or so. The plastic bottle even features a K&N breather and CNC-cut mounting bracket.

If left stock and oil levels maintained at proper levels, your engine will operate as engineered. The addition of a oil catch can will only serve as an extra filter – a preventative measure. Yet if modified, the addition of a catch can is almost mandatory to ensure a healthy, equalized crankcase atmospheric pressure as well as a clean, uncontaminated intake charge – which will result in greater engine efficiency and thereby, increased acceleration and horsepower.

Kevin,could you just illuminate you’re catch can and weld a bung into a free flow exhaust and have it all suckers out by exhaust vacuum

I’ve done a few videos on this exact topic. Check out the YouTube channel!