The Watercraft Journal is always reviewing the latest in PWC performance and innovation, so it came as no surprise when they teamed up with JD from JD’s WaterWorld to take a first-hand look at the Supercharger Belt Tensioner with stainless-steel Idler Pulley from Kawi Performance (KP).

If you own an Ultra 300 or Ultra 310 then you are undoubtedly well-acquainted with the Supercharger Belt Tensioner assembly. Anyone who rides in salt water will appreciate the engineering that went into this innovative component, which was designed specifically to improve performance while reducing maintenance and downtime.

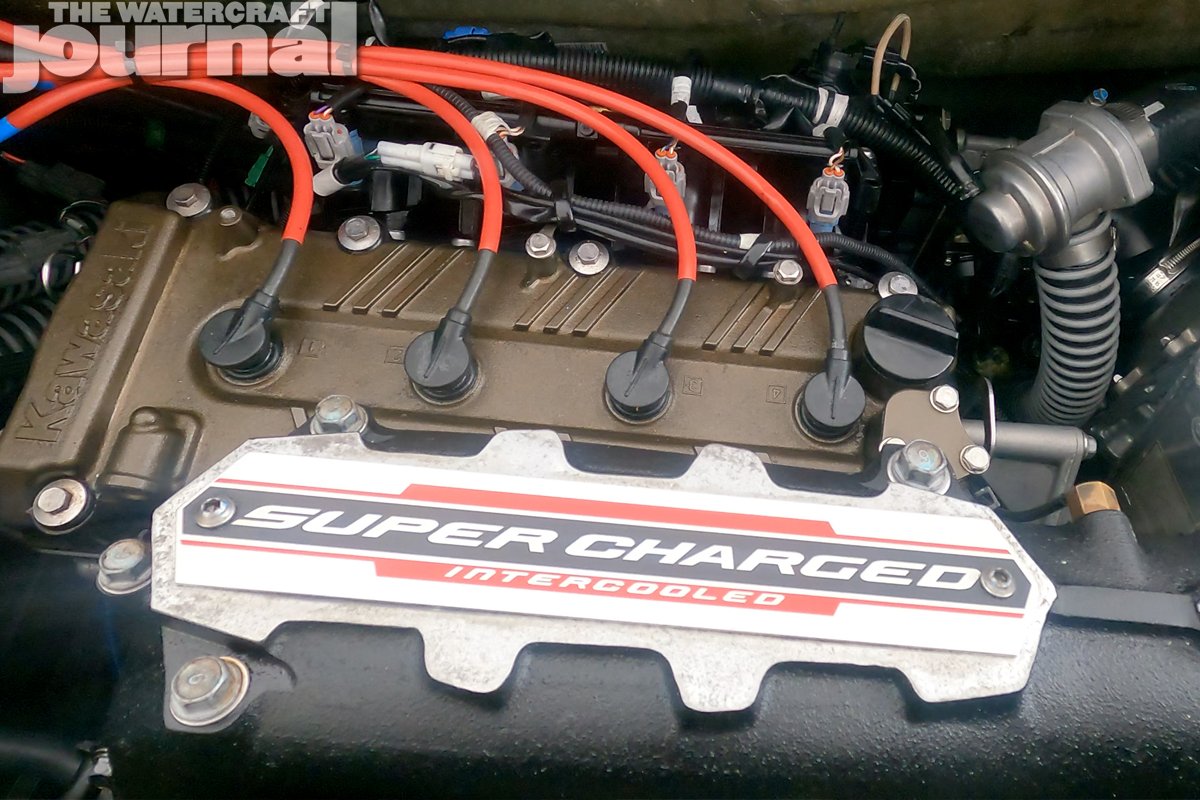

For readers scratching their heads at this point, all Kawasaki Ultra 310s are boosted by an Eaton Twin Vortices Series (TVS) belt-driven supercharger. As JetSkis jump in and out of the water, the engine and supercharger are subjected to extreme loads.

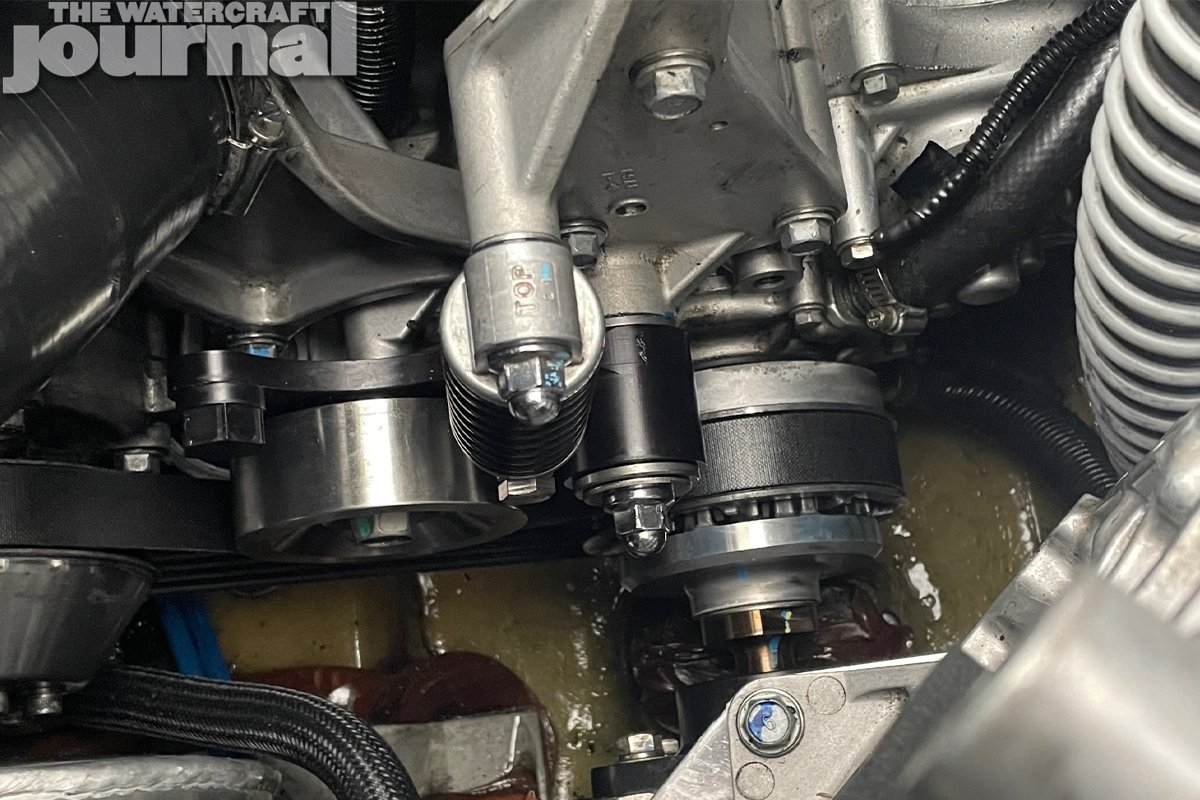

To reduce the shock of this load, Kawasaki engineers developed multiple dampening systems: One is integrated into a liquid-cooled supercharger gearbox; the other is the combination of a serpentine drive-belt and tensioner assembly.

The tensioner is designed to automatically release tension on the belt, which then allows a small amount of slip, thereby absorbing the shock of loading and unloading the jet pump. When the stock assembly binds, however, it fails to provide the proper tension needed, and allows the belt to experience an excessive amount of slip.

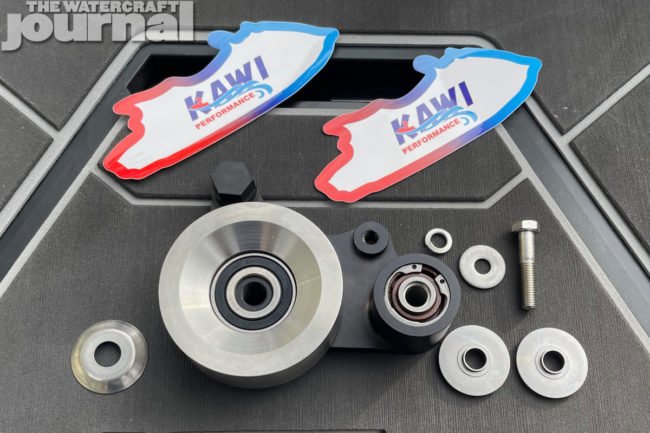

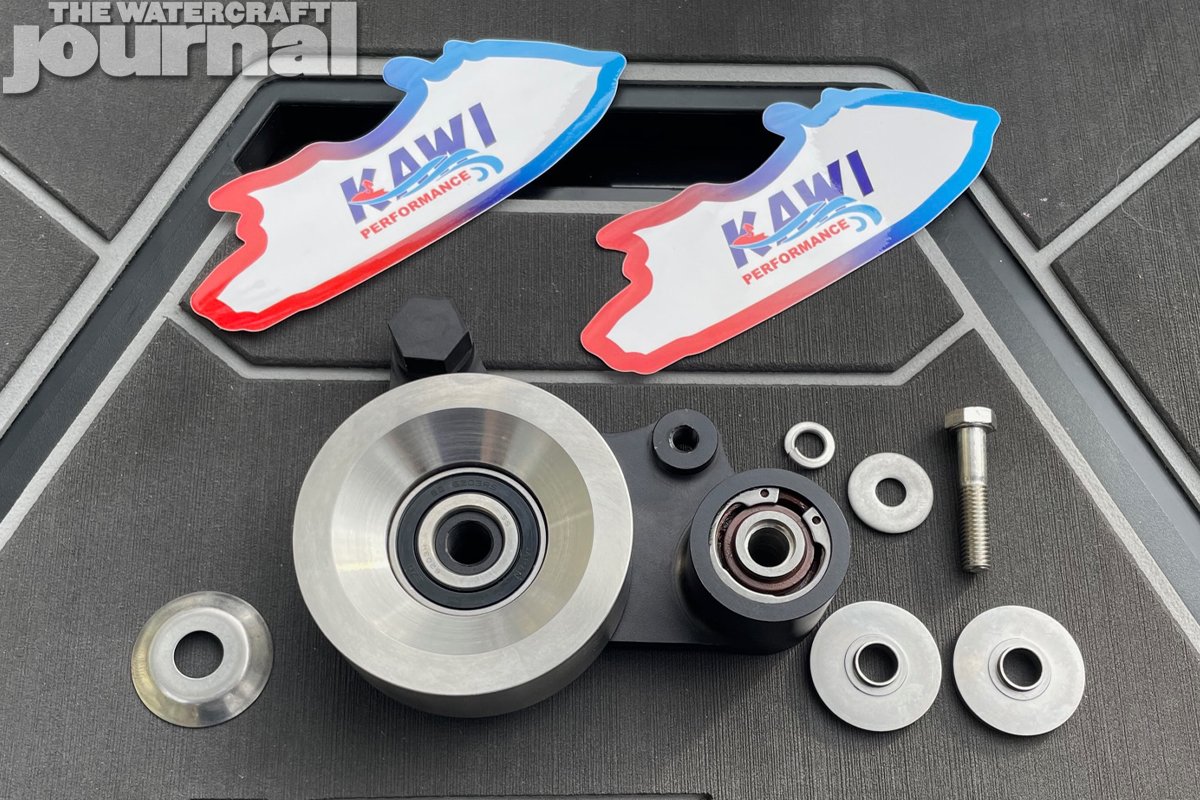

Kawi Performance has completely re-engineered the stock tensioner to fix this problem! These tensioners are made from billet aluminum with a black hard coat. They also include 303 stainless washers, 303 stainless bushings, 304 stainless snap rings, Viton seals with 316 stainless springs, and stainless bearings.

By utilizing sealed bearings instead of a pivot bushing, there is no longer the need to constantly disassemble and grease the tensioner. The KP tensioner provides an additional 5-10 pounds on the belt, which extends the belt’s life by reducing slippage.

While those looking to install the KP tensioner can use the stock steel pulley or an aftermarket aluminum pulley, The Watercraft Journal was provided with KP’s stainless steel pulley, complete with a stainless bearing and stainless dust guard. While steel pulleys rust and aluminum pulleys pit and corrode, the KP idler is made of marine-grade stainless steel. The idler includes a pre-installed stainless bearing.

Bearings are replaceable as many times as needed, and can be purchased from Kawi Performance. It is recommended that riders replace the idler pulley bearing each season to ensure peak performance. The KP Tensioner and pulley installs with the same hardware as the stock unit, and the process should not be difficult for those acquainted with performing regular maintenance on the Ultra 300 or 310.

Always inspect your belt closely, and replace when necessary to avoid a failure out on the water. Having a Kawasaki Ultra 300 or 310 service manual on-hand is always a good idea when performing maintenance or installations. We put together a comprehensive unboxing, installation, and overview video on the KP Tensioner Assembly below: